Strong Guidance for Miniaturization - PM News

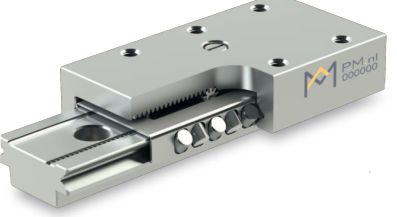

Industrial manufacturing of high-precision miniaturized positioning systems to customer-specific designs generally require sophisticated production strategies. As filigrain miniature roller tables can be integrated with cage control approaches, they become suitable for highly dynamic applications.

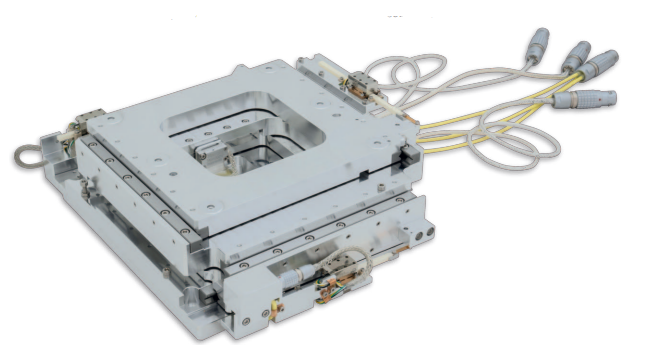

Miniaturization and system integration are significant trends in many areas of industry. While the compactness of motion systems is an essential basic virtue in medical technology, aerospace engineering, and optical equipment, semiconductor, and electronics production specifications also include a high level of dynamics.

Motion systems and their drive, guidance, and measurement systems are following this trend. While numerous standard products are available for large and medium-sized guide rails and slides, suppliers’ ranges start to thin out as the level of miniaturization increases. At the same time, the sheer variety of applications and their specific requirements mean that custom developments or modifications are often essential.

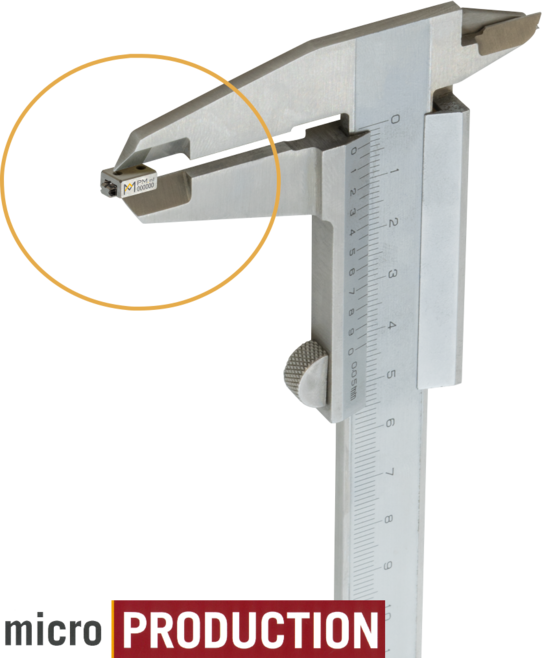

The bearing units and structural components are really the heart of the guides and positioning systems and are completely milled, turned, ground, bored and hardened by PM. The company produces 95 percent of the mechanical components in-house, including the bearing cages (Figure 1). Ball screws, piezo and linear motor drives, linear encoders, and sensors are obtained from external suppliers. If the guides are used under critical environmental conditions, ceramic components will also be fitted. They provide exceptionally high wear resistance and rigidity. Thanks to an enlargement of the contact surfaces and a zero-backlash construction, even this tiny product can do great things. It can reach accelerations of up to 200 m/s2 and speeds of up to 2 m/s.

Click here to read more

- PM News